5 Signs of Reliable Rubber Cable Suppliers

Reliable rubber cable suppliers show certain clear signs that set them apart. First, their product quality is evident in durable insulation materials like EPR or Neoprene, designed to resist heat, moisture, and oils while maintaining proper conductor properties and precise cable lengths. Second, trustworthy suppliers provide full certifications such as IEC and CE marking, proving compliance with industry standards without needing customers to ask. Third, they offer expert technical support by understanding specific project requirements and recommending suitable cables instead of generic options. Fourth, clear communication and honest pricing build customer confidence throughout the purchasing process. Lastly, dependable delivery schedules with well-managed stock plus positive industry reputation ensure timely order fulfillment and lasting client relationships.

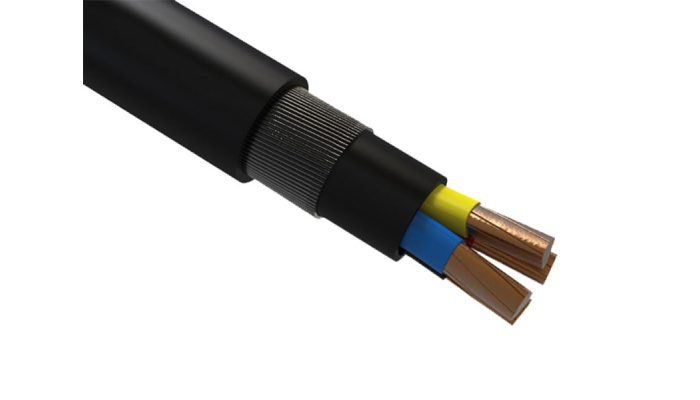

1. Product Quality and Clear Quality Indicators

Reliable rubber cable suppliers prioritize product quality by using durable insulation materials like EPR or Neoprene, which resist heat, moisture, oils, chemicals, and mechanical wear. The conductor must be made from bright, soft copper with the correct cross-sectional area to ensure both flexibility and proper conductivity. Accurate cable length is another important factor, typically 100 meters with a tolerance of ±0.5 meters, to meet installation standards and avoid material waste. The sheath quality can be assessed by checking the uniformity of the compressed braided net, which indicates solid production processes without slippage. Proper shielding layers should be dense and evenly distributed to effectively protect against electromagnetic interference. High-quality cables pass strict resistance tests for heat, abrasion, moisture, and oils, demonstrating their ability to withstand real working conditions. The surface of the cable should be smooth and uniform, free from visible defects, reflecting consistent manufacturing standards. Insulation thickness must remain consistent along the entire length, ensuring safety and proper performance. Trustworthy suppliers provide product samples or detailed test results, allowing customers to verify quality before purchase. Additionally, clear quality markings and batch numbers on the cable help trace manufacturing details and maintain accountability throughout the supply chain.

2. Certifications and Compliance with Industry Standards

Reliable rubber cable suppliers provide clear evidence of compliance with international standards like IEC, BS, and VDE. These certifications prove that the cables meet essential safety, performance, and environmental requirements. For example, CE marking shows the product aligns with European safety and environmental rules, while RoHS compliance ensures the cable is free from harmful substances, benefiting both users and the environment. A trustworthy supplier doesn’t wait for customers to ask; they proactively share detailed testing reports and certificates covering electrical properties, mechanical strength, and resistance to environmental factors. This transparency builds confidence that the products adhere to current market and regulatory demands. Additionally, third-party testing or certification adds an extra layer of credibility to their claims. Compliance with these standards means the cables are suitable for specialized sectors like marine, renewable energy, and industrial automation, where strict regulations apply. Certifications also simplify approval in regulated projects or government contracts. Good suppliers regularly update their certifications to reflect changes in standards or product improvements, ensuring ongoing reliability and legal compliance.

- Suppliers should provide certificates showing compliance with international standards such as IEC, BS, and VDE.

- CE marking indicates that the product meets European safety and environmental requirements.

- RoHS compliance confirms that the cable is free from hazardous substances, making it safer for users and the environment.

- Testing reports and certificates should be available proactively without the customer needing to ask.

- Documentation should include details on electrical properties, mechanical strength, and environmental resistance.

- Suppliers following updated standards ensure their products meet current market and regulatory demands.

- Presence of third-party testing or certification adds credibility to supplier claims.

- Compliance with industry standards means the cable is fit for use in specialized sectors like marine, renewable energy, and industrial automation.

- Certifications also support easy approval processes in regulated projects or government contracts.

- The supplier should update certifications regularly to reflect any changes in standards or product improvements.

3. Comprehensive Product Knowledge and Technical Expertise

Reliable rubber cable suppliers demonstrate deep understanding of cable types and their specific uses. They know how to recommend the right cable based on environmental factors like heat, UV exposure, or oil contact. For example, they can explain why a Neoprene-insulated cable performs better in oil-rich environments compared to standard rubber. Instead of offering generic products, they ask detailed questions about the buyer’s project to ensure recommendations truly match the application. Their technical know-how extends to current industry regulations and standards, helping customers avoid costly compliance issues. They stay updated on new technologies that enhance cable performance or simplify installation, offering guidance on proper techniques to prevent damage and ensure long-lasting cables. Good suppliers also provide training or technical support resources, making complex information accessible by avoiding jargon. By understanding customer challenges and tailoring solutions, they build trust and foster long-term partnerships.

4. Strong Customer Support and Transparent Communication

Reliable rubber cable suppliers provide consistent support throughout the entire buying process, from helping customers choose the right cable to troubleshooting any issues after installation. They respond quickly to questions and give accurate information about stock levels and delivery times, avoiding vague or uncertain answers. Pricing is always clear, with no hidden charges, costs for cable length, taxes, and delivery are spelled out upfront. Bulk discounts and payment terms are communicated early to help customers plan their budgets effectively. After delivery, dependable suppliers follow up to ensure satisfaction and address any problems that may arise. Technical support remains available to assist with installation or operational questions, helping reduce downtime. They keep communication open across multiple channels like phone, email, and live chat for customer convenience. Along with the product, clear documentation such as datasheets and user manuals is provided. These suppliers also encourage and listen to customer feedback, using it to improve their services and products over time.

5. Reliable Delivery, Stock Availability, and Industry Reputation

A reliable rubber cable supplier maintains a well-organized inventory that matches current market demand, allowing them to quickly fulfill orders, including urgent and bulk requests. This minimizes delays and helps keep projects on schedule. They offer flexible delivery options, such as same-day shipping or scheduled dispatches, tailored to meet specific timeline requirements. Effective logistics management ensures cables arrive on time and in good condition, with clear tracking systems that keep customers informed throughout the shipping process. The supplier’s strong industry reputation is reflected in positive reviews and testimonials from contractors, engineers, and industrial clients who have experienced consistent performance. Long-term partnerships with reputable companies demonstrate trust and reliability, while experience managing diverse, complex projects adds confidence in their ability to deliver under pressure. Transparent business practices and ethical standards further support their standing, with case studies and references available to show proven competence and dependable service.

Frequently Asked Questions

1. How can you tell if a rubber cable supplier tests their products for quality?

Reliable suppliers often have clear descriptions of their quality testing processes, such as compliance with industry standards and use of certified laboratories. They might share test reports or certifications that prove they check factors like insulation resistance, durability, and flame retardancy before selling cables.

2. What kind of certifications should a trustworthy rubber cable supplier have?

Look for suppliers with recognized certifications like ISO 9001 for quality management, UL listing, or other specific approvals relevant to electrical products. These certificates show the supplier meets established safety and manufacturing standards consistently.

3. Why is it important for rubber cable suppliers to have technical support or expertise?

Technical support indicates the supplier understands cable specifications and can guide you to the right product for your needs. This saves time and reduces errors, especially when dealing with complex installations or compliance requirements, showing the supplier values customer success, not just sales.

4. What role does a supplier’s delivery reliability play in judging their trustworthiness?

Timely and accurate delivery is critical. Reliable suppliers have a good track record of meeting deadlines and providing the correct products. This consistency helps keep projects on schedule and avoids costly delays, which reflects their ability to manage supply chain and customer demands effectively.

5. How important is it for rubber cable suppliers to offer detailed product information and transparency?

Suppliers who provide thorough product details, including specifications, material composition, and application guidelines, demonstrate transparency and build trust. This information helps buyers make informed decisions and ensures the cables meet the necessary safety and performance requirements for their projects.

TL;DR Trustworthy rubber cable suppliers deliver quality products with durable insulation, precise conductor specs, and proven resistance to harsh conditions. They hold certifications like IEC and CE, share documentation proactively, and bring deep technical expertise tailored to project needs. Expect clear, honest communication, supportive customer service, and transparent pricing. Reliable suppliers maintain good stock levels, ensure timely deliveries, and have solid industry reputations backed by positive feedback and lasting partnerships.