How Drum Handling Equipment Cuts Down Downtime?

In the fast-paced world of industrial operations, every second counts. Downtime can be a costly setback that hampers productivity and drains resources. Enter drum handling equipment—a game-changer in the quest for efficiency. These tools are designed to streamline processes involving heavy drums, ensuring smoother workflows and minimizing delays. Whether your facility handles hazardous materials or simply needs to move large quantities of substances swiftly, investing in proper drum handling solutions could prove vital. Let’s explore how this specialized equipment not only cuts down downtime but also enhances overall operational effectiveness.

Common Causes Of Downtime In Industrial Settings

Downtime in industrial settings can stem from various factors, impacting productivity and profitability. Equipment breakdown is a primary culprit. When machinery fails, operations come to a halt until repairs are made.

Another common issue is poor maintenance practices. Neglecting routine inspections can lead to unexpected failures, causing significant delays in production schedules.

Human error also plays a role. Mistakes during operation or handling processes can result in accidents or inefficiencies that disrupt workflows.

Supply chain interruptions further exacerbate downtime. Delays in receiving essential materials hinder manufacturing capabilities and create bottlenecks on the production line.

Inadequate training for staff can contribute to inefficiencies. Employees lacking proper knowledge may struggle with equipment use, leading to slower operations and increased risk of incidents. Each of these factors underscores the need for effective solutions like drum handling equipment to mitigate downtime risks.

Ways Drum Handling Equipment Can Reduce Downtime

Drum handling equipment streamlines processes, making operations smoother than ever. By automating the lifting and moving of heavy drums, this equipment minimizes manual labor’s strain on workers.

With forklifts specially designed for drum transport, staff can quickly load and unload materials without unnecessary delays. This efficiency translates to faster turnaround times in production lines.

Another advantage is the reduction of spills and accidents. Properly designed drum handling tools ensure safer transportation, which decreases the likelihood of costly cleanup sessions or injuries that could halt progress.

Moreover, these tools are versatile. They can handle various drum sizes and weights, allowing businesses to adapt swiftly to changing demands without significant downtime interruptions.

Ease of use means less training time for employees. When your team spends less time learning complex systems, productivity increases immediately.

Types Of Drum Handling Equipment Available

Drum handling equipment comes in various types, each designed to meet specific needs. One popular option is the drum dolly. This wheeled platform allows for easy transportation of heavy drums across flat surfaces.

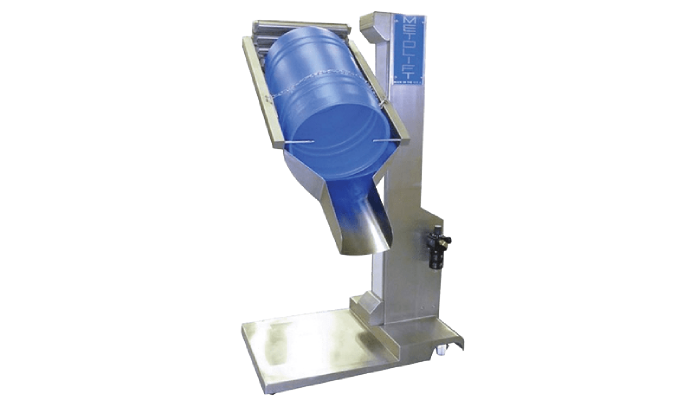

Another essential tool is the drum lifter. These devices can lift and move barrels with minimal physical effort, making them ideal for tight spaces where manual handling isn’t feasible.

For those needing to pour or dispense contents safely, a drum pump provides an efficient solution. It minimizes spills and ensures precise control over liquid transfer.

And let’s not forget about drum racks. They optimize storage by securely holding multiple drums in place while keeping your workspace organized and clutter-free.

Investing in the right type of drum handling equipment can significantly enhance efficiency and safety within any industrial setting. Each piece serves a unique purpose, tailored to specific tasks that streamline operations.

Case Study: Real-Life Example Of Reduced Downtime With Drum Handling Equipment

A manufacturing facility faced frequent downtime due to manual drum handling. Workers struggled with heavy drums, leading to injuries and production halts.

After investing in drum handling equipment, the situation changed dramatically. The company introduced automated drum rollers and lifters, reducing physical strain on employees.

Within a month, they reported a 30% decrease in downtime related to drum movements. Employees could transport materials faster without risking injury.

Safety incidents dropped significantly as well. With the new equipment in place, workers felt more secure performing their tasks. This investment not only boosted productivity but also improved employee morale.

The results were clear: efficient use of specialized equipment led to smoother operations and substantial time savings for the entire facility.

Cost And Time-Saving Benefits Of Investing In Drum Handling Equipment

Investing in drum handling equipment can yield significant cost savings for businesses. With reduced labor costs, companies can allocate resources more efficiently. Automating tasks minimizes the need for manual lifting and transporting, decreasing the risk of workplace injuries.

Time is another critical factor. Streamlined operations mean quicker turnaround times. Workers spend less time maneuvering heavy drums and more time focusing on their core responsibilities.

Moreover, this equipment often enhances inventory management. Efficiently moving and storing drums leads to better organization in warehouses or production areas.

Long-term savings also come from decreased maintenance costs associated with fewer accidents and damage to products. By enhancing safety protocols, businesses lower insurance premiums over time as well.

Investing in drum handling equipment not only improves productivity but also contributes to a healthier bottom line through various indirect benefits.

Safety Precautions When Using Drum Handling Equipment

When using drum handling equipment, safety should always be the top priority. Before operating any machinery, ensure you’re trained and familiar with its functions.

Wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and steel-toed boots to safeguard against potential hazards.

Inspect the equipment regularly for signs of wear or damage. A quick check can prevent accidents down the line.

Always secure drums properly before lifting. Use straps or clamps designed for your specific type of drum to avoid spills or falls.

Maintain clear communication with team members during operation. A simple hand signal can make all the difference in ensuring everyone’s safety around moving machinery.

Keep work areas tidy and free from obstructions. Cluttered spaces can lead to slips and falls when handling heavy loads like drums. Being mindful of these precautions creates a safer workplace environment for everyone involved.

Conclusion

Drum handling equipment plays a vital role in minimizing downtime in industrial settings. By understanding the common causes of delays and implementing effective solutions, businesses can optimize their operations. The various types of drum handling equipment available provide flexibility and efficiency for transporting heavy loads safely.

When companies invest in this specialized gear, they not only enhance productivity but also foster a safer working environment. Real-life case studies illustrate how these tools have transformed workplaces by significantly reducing time lost to manual handling errors or equipment failures.

Moreover, the cost savings associated with decreased downtime make drum handling equipment an attractive investment for any business engaged in heavy lifting tasks. With proper safety precautions, teams can operate confidently while maximizing performance.

The integration of reliable drum handling solutions is essential for any operation aiming to improve workflow and maintain competitive advantages. Embracing these innovations could be the key to unlocking your facility’s full potential.