Canal Dredge Costs: What You Need to Know?

Canal dredging costs can vary widely depending on several factors, as shown by the recent Longboat Key project. Initial estimates were very high due to outdated volume data, but updated surveys significantly lowered both dredging volume and cost, emphasizing how crucial accurate surveys are for cost control. Besides dredging, environmental mitigation, especially seagrass restoration, added substantial expenses that were initially underestimated. Other major cost drivers include engineering and permitting fees, which can be lengthy and complex due to multiple agencies involved. Equipment mobilization, sediment type, disposal options, and water management also affect budgets. Overall, careful planning and up-to-date data help manage expenses while meeting environmental requirements.

How Sediment Type and Volume Affect Dredging Costs?

The volume of sediment to be canal dredge plays a major role in overall project costs. Larger volumes require more handling, longer equipment run-times, and increased disposal efforts, all of which raise expenses. For example, reducing dredging volume from 127,000 to 40,000 cubic yards can drastically cut costs, as seen in recent canal projects. Sediment type also has a big impact: soft muck is easier to remove and demands less power, but managing its high water content can complicate dewatering and disposal. Harder sediments like clay or gravel need more equipment power, leading to higher fuel consumption and faster machinery wear, which increase maintenance costs. Thick sediment layers slow down production rates, extending project duration and labor expenses. Additionally, sediment characteristics influence disposal options, contaminated or fine sediments often require specialized handling or treatment, driving costs higher. Variations in sediment density affect volume-to-weight conversions, impacting transportation and disposal fees. Environmental concerns tied to sediment type may call for extra mitigation measures to protect aquatic habitats, adding to the budget. Accurate sediment profiling before work begins helps prevent scope creep and unexpected cost increases, while updated surveys that refine sediment volume can significantly reduce dredging and disposal expenses.

- Dredging volume directly impacts project cost; higher volumes increase material handling, disposal, and run-time expenses.

- Sediment type affects equipment wear, fuel consumption, and run-time efficiency; soft muck is easier but may have water management issues.

- Harder sediments like clay or gravel require more power and increase equipment maintenance costs.

- Thicker sediment layers slow production rates, raising project duration and labor costs.

- Water content and sediment consistency influence dewatering needs and disposal methods, affecting overall expenses.

- Sediment characteristics determine disposal options; contaminated or fine sediments may need specialized handling increasing cost.

- Accurate sediment profiling before dredging reduces risk of scope creep and unexpected expenses.

- Sediment volume reduction through updated surveys can greatly lower dredging and disposal costs.

- Variations in sediment density affect volume-to-weight conversions, influencing transportation and disposal pricing.

- Sediment type also dictates environmental mitigation measures, as some sediments pose higher risk to aquatic habitats.

Engineering and Permitting Costs in Canal Projects

Engineering design is a crucial step in canal dredging projects, covering tasks like project planning, sediment analysis, dredging method selection, and environmental assessments. Key engineering activities include hydrographic surveys, geotechnical studies, and habitat impact analysis, which help define the project’s scope and identify potential challenges early on. Permitting is another significant cost and timeline factor, involving coordination with multiple agencies such as the U.S. Army Corps of Engineers (USACE), Environmental Protection Agency (EPA), and state environmental departments. The complexity of the permitting process depends heavily on factors like project size, sediment characteristics, disposal methods, and the environmental sensitivity of the site. For example, the presence of protected species, historic sites, or sensitive habitats can increase the regulatory hurdles, requiring more detailed documentation and mitigation plans. Permit preparation and application fees can reach into the millions, especially for large-scale projects with stringent environmental requirements. Delays or revisions triggered by permit conditions often lead to higher overall costs due to redesign or schedule slippage. To manage these risks, mitigation planning and monitoring are commonly integrated into the engineering budget to meet permit conditions. Engaging permitting experts early in the planning phase helps avoid costly redesigns and keeps the project on track. This proactive approach can streamline regulatory approvals and reduce unexpected expenses tied to compliance.

Impact of Mobilization and Equipment on Budget

Mobilization involves transporting and setting up dredging equipment like dredges, barges, and pipelines at the project site. Because mobilization is a fixed cost, it tends to have a greater impact on smaller projects, where the expense is spread over fewer dredged cubic yards, resulting in higher per-unit costs. For projects executed in multiple phases or over several years, mobilization may need to be repeated, which adds cumulatively to the overall budget. The choice of equipment plays a significant role in both capital and operational costs. Hydraulic dredgers, for example, generally require higher upfront investment compared to mechanical dredgers but can offer better fuel efficiency and environmental controls. Larger, modern dredgers come with higher capital costs but often improve productivity, reduce fuel consumption, and minimize environmental disturbance. These factors influence not only the project’s run-time but also ongoing maintenance and fuel expenses. The number of operational hours per day affects equipment utilization: longer shifts usually lower the unit cost but may be limited by local regulations. Equipment downtime, whether from scheduled maintenance or environmental restrictions, can extend project duration and increase total costs. Mobilization logistics depend heavily on site accessibility and proximity to equipment storage, as well as the condition of local infrastructure, which can complicate transport and setup. A comprehensive budget should account for both capital costs and operational expenses related to equipment to fully understand their impact on the overall dredging project cost.

Environmental Mitigation and Seagrass Restoration Costs

Environmental mitigation, especially seagrass restoration, can be one of the most significant and often underestimated expenses in canal dredging projects. Recent estimates from Longboat Key show seagrass mitigation costs rising sharply from $1 million to $3.6 million. This increase is largely driven by the loss of natural sand sources, which forces project managers to adopt alternative strategies like creating shallow sand areas to encourage seagrass growth. These mitigation plans must comply with strict regulatory requirements and permit conditions, often requiring detailed habitat restoration efforts. Restoration itself is a multi-step process involving planting seagrass, continuous monitoring, and adaptive management to ensure the plants survive and thrive. In sensitive environments, these environmental costs can even surpass the dredging expenses. Additionally, budgets must account for long-term maintenance and the risk of mitigation failure, which can lead to further costs down the line. Permit agencies closely scrutinize mitigation proposals, and inadequate plans can cause delays and added expenses. The cost of mitigation varies widely depending on project size, habitat sensitivity, and local environmental conditions. Conducting early environmental assessments helps reduce unexpected costs and allows mitigation efforts to be better integrated into the project scope. Community and stakeholder input may also influence mitigation methods, sometimes increasing complexity and overall budget requirements.

Permitting Process and Regulatory Requirements in the U.S.

In the U.S., canal dredging projects require navigating a complex permitting process overseen by multiple agencies, including the U.S. Army Corps of Engineers (USACE), the Environmental Protection Agency (EPA), and relevant state authorities. Key permits typically include the Clean Water Act Section 404 permit, which governs the discharge of dredged or fill material into waters, and the Section 401 Water Quality Certification issued at the state level to ensure water quality standards are met. If the dredged material is planned for ocean disposal, permits under the Marine Protection, Research and Sanctuaries Act (MPRSA) are also necessary. The permitting timeline can range from six to eighteen months or longer, depending on the project’s complexity and environmental sensitivity. Detailed environmental impact assessments are mandatory, focusing on aquatic habitats, endangered species, and overall water quality. Public notice and comment periods allow community input, which can significantly influence permit approval or conditions. Compliance with the Endangered Species Act and the National Historic Preservation Act is required to protect vulnerable species and cultural resources. Additionally, local permits related to stormwater management, wetlands, or coastal zones may be needed. Often, permits come with conditions requiring mitigation plans, such as habitat restoration or seagrass replacement, which can add to project costs and timelines. Delays in securing permits can substantially affect the dredging schedule and budget, making early and thorough preparation essential for managing risks and controlling costs.

Disposal Methods and Water Management Expenses

Disposal of dredged material is a key cost factor in canal dredging projects. Common options include settling basins, dewatering pads, landfills, or beneficial reuse such as habitat restoration. The location of disposal sites greatly affects transportation expenses, which can quickly add up if the site is far from the dredging area. When sediments are contaminated, special handling and regulatory approvals are required, often increasing disposal costs significantly. Water management during dredging is equally important. The water used to move and process sediments must be treated to remove suspended solids and contaminants before it can be discharged or reused. Treatment methods might involve polymers, filters, or dedicated treatment plants, all of which add complexity and expense. Effective water management includes separation, treatment, storage, and proper disposal of dredging effluent to meet environmental permits and reduce impacts. Dewatering sediment reduces its volume and lowers transport costs but requires appropriate equipment and space, which can be limited. Planning disposal and water management early in the project helps optimize logistics and control costs. Unforeseen challenges with disposal or water handling can cause delays and increase the overall budget, so incorporating these factors into initial project plans is essential.

Operational Run-Time and Efficiency Effects on Costs

Operational run-time plays a crucial role in controlling canal dredging costs. Longer daily hours allow equipment to be used more efficiently, spreading fixed costs over more production and lowering the unit cost of dredging. While 24-hour operations maximize productivity, they are often limited by noise restrictions, lighting needs, and local ordinances, which require careful scheduling. Shorter operating periods extend the project timeline, increasing indirect expenses like staff wages, equipment rental fees, and mobilization costs. Efficient equipment use not only improves run-time but also reduces fuel consumption and wear, which lowers overall operational expenses. Factors like weather and environmental restrictions can limit allowable run-times, necessitating contingency plans to avoid costly delays. Skilled operators and diligent maintenance directly impact run-time efficiency by minimizing downtime and preventing equipment failures, which otherwise add significant expense. Balancing dredge schedules with regulatory compliance and community concerns is essential to maintain steady progress. Additionally, optimizing production rates based on sediment characteristics and equipment capabilities helps reduce total costs by minimizing wasted effort. Delays caused by equipment breakdowns or adverse environmental conditions increase project costs and risk budget overruns. Therefore, thorough planning of operational hours aligned with site conditions and regulations is key for accurate cost estimation and effective project scheduling.

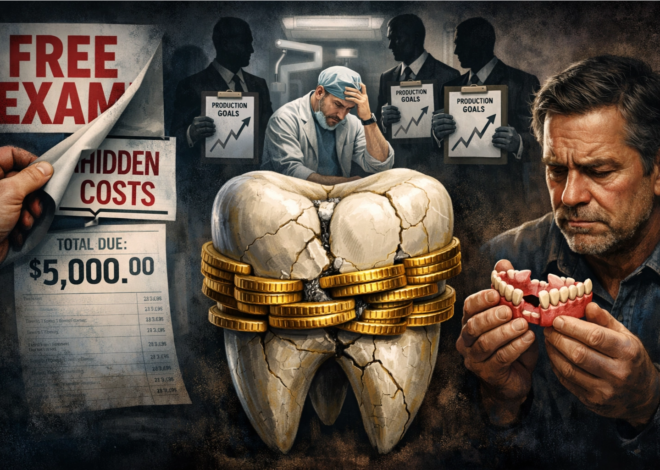

Funding Challenges and Alternatives for Canal Dredging

Funding canal dredging projects often faces hurdles from the start. Initial proposals like property tax millage can meet public resistance, leading to delays or deferrals, as seen in recent projects where community concerns stalled funding approval. Because of this, project planners frequently turn to alternative sources such as grants, state or federal programs, and private partnerships to secure necessary financing. Even before large-scale funds are confirmed, a relatively small amount, for example, around $500,000, is usually needed to begin surveys, engineering studies, and planning efforts. These early costs are critical but can be tough to fund without solid backing.

Complex permitting and environmental mitigation add layers of upfront expenses that complicate budgeting and funding strategies. For instance, environmental requirements like seagrass restoration can dramatically increase costs, which funders may not anticipate initially. This uncertainty in funding can delay project start dates, which in turn raises the total cost due to inflation and changing site conditions over time.

Engaging stakeholders early and maintaining transparent communication can improve the chances of securing and sustaining funding. Communities and funding bodies respond better when they understand the project’s benefits, such as improved navigation, enhanced property values, and long-term economic gains. Flexible funding approaches, such as breaking the project into phases or establishing cost-sharing arrangements among local governments and private entities, can also ease financial burdens and spread costs over time.

Best Practices for Survey Accuracy and Cost Control

Frequent, high-resolution hydrographic surveys are essential for reducing uncertainties around dredging volumes and project scope. Updated surveys help avoid overestimating sediment amounts, which can prevent unnecessary dredging activities and major cost overruns. Engaging engineers and permitting specialists early in the process identifies potential challenges upfront, minimizing expensive redesigns later. Budgeting conservatively for environmental mitigation, such as seagrass restoration, helps avoid unexpected expenses during execution. Maximizing dredge run-times and deploying efficient equipment lowers unit costs by improving productivity. Careful disposal planning, including choosing nearby and cost-effective sites, reduces transportation and treatment expenses. Transparent communication with the community and regulators supports smoother permitting and funding approval, which can save time and money. Continuously monitoring progress and adjusting project plans during dredging keeps costs in check and maintains schedules. Finally, documenting lessons learned from each project improves future cost estimates and decision-making, while integrating environmental considerations early reduces risks of delays and costly changes.