Environmental Impact of Different Condenser Tube Cleaning System

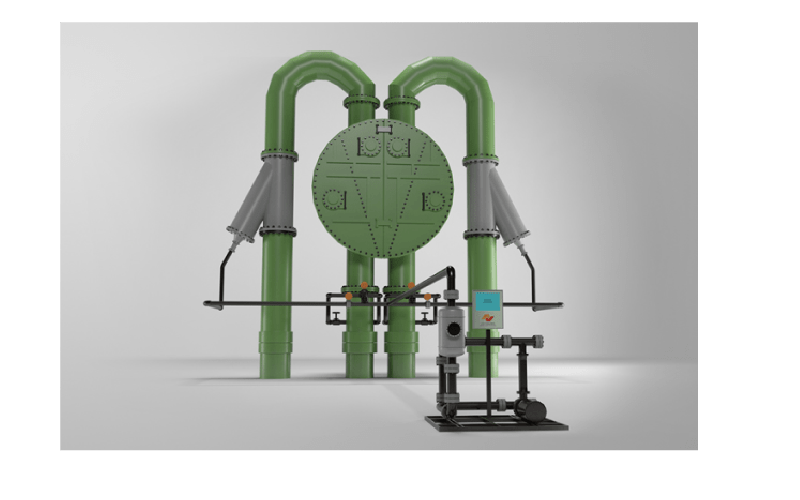

Condenser tube cleaning systems are integral to maintaining the efficiency and longevity of cooling systems across various industries. However, their environmental impact is a growing concern as industries strive to balance operational performance with ecological responsibility. Traditional cleaning methods, while effective, can contribute to environmental issues such as chemical pollution, excessive water usage, and high energy consumption. As awareness of environmental sustainability increases, there is a significant push towards adopting eco-friendly condenser tube cleaning systems. These systems aim to minimize their environmental footprint by incorporating advanced technologies and practices that reduce waste, conserve resources, and lower emissions. This exploration delves into the environmental benefits and impacts of different condenser tube cleaning systems, evaluating their contributions to resource conservation, pollution reduction, and overall ecological sustainability.

Environmental Benefits Of Eco-Friendly Condenser Tube Cleaning Systems

Eco-friendly condenser tube cleaning system are designed with the primary goal of reducing their environmental impact while maintaining high cleaning efficiency. These systems often utilize advanced technologies such as ultrasonic cleaning, which employs high-frequency sound waves to remove deposits without the need for harsh chemicals. This method not only reduces the chemical load on the environment but also minimizes water consumption compared to traditional cleaning methods. Another eco-friendly approach is the use of biodegradable and non-toxic cleaning agents that break down into harmless substances, thereby reducing the risk of pollution. Additionally, many modern systems are designed to be energy-efficient, incorporating features that optimize power usage and reduce greenhouse gas emissions. By adopting these eco-friendly technologies, industries can achieve effective condenser tube cleaning while contributing to environmental conservation and aligning with sustainable practices.

Chemical Free Condenser Tube Cleaning Systems Reduce Environmental Pollution

Chemical-free condenser tube cleaning systems represent a significant advancement in reducing environmental pollution associated with traditional cleaning methods. Traditional cleaning approaches often rely on corrosive chemicals and solvents that can lead to hazardous waste, soil contamination, and water pollution. In contrast, chemical-free systems utilize alternative technologies such as mechanical brushes, air blasts, or high-pressure water jets to clean condenser tubes without introducing harmful substances into the environment. For example, systems that use high-pressure water jets can remove scale and debris effectively without chemical additives, thus eliminating the risk of chemical runoff and associated pollution. These systems also tend to produce less waste and have lower disposal requirements, further reducing their environmental impact. By shifting towards chemical-free condenser tube cleaning solutions, industries can significantly mitigate their ecological footprint and support more sustainable practices.

Waste Management Practices Of Various Condenser Tube Cleaning Systems

The waste management practices of condenser tube cleaning systems play a crucial role in determining their overall environmental impact. Different cleaning methods generate varying types and quantities of waste, which must be managed properly to minimize environmental harm. Traditional cleaning systems often produce sludge and chemical waste that require proper disposal to prevent contamination of soil and water sources. In contrast, modern condenser tube cleaning systems are increasingly incorporating waste minimization strategies, such as recycling and reusing cleaning solutions, to reduce the volume of waste generated. Some systems also feature advanced filtration technologies that capture and manage particulate matter, enabling the safe disposal or recycling of waste products. Effective waste management not only reduces the environmental footprint of cleaning operations but also helps industries comply with regulatory requirements and promote sustainable practices. By evaluating and improving waste management practices, industries can enhance the environmental performance of their condenser tube cleaning systems.

Impact Of Condenser Tube Cleaning System Water Usage On Resource Conservation

Water conservation is a critical aspect of environmental sustainability, and condenser tube cleaning systems play a significant role in this regard. Traditional cleaning methods often involve substantial water usage, which can strain local water resources, particularly in regions facing water scarcity. In contrast, modern condenser tube cleaning systems are designed to be more water-efficient, employing technologies that reduce water consumption while maintaining effective cleaning performance. For instance, closed-loop water recycling systems can capture and reuse water from cleaning processes, minimizing the need for fresh water and reducing wastewater discharge. Additionally, advanced cleaning technologies, such as ultrasonic and air-blast systems, require less water compared to traditional methods. By adopting water-efficient condenser tube cleaning systems, industries can contribute to resource conservation, reduce their environmental impact, and support global efforts to manage water resources sustainably.

Energy Consumption And Efficiency Of Different Condenser Tube Cleaning Systems

Energy consumption is another important factor in assessing the environmental impact of condenser tube cleaning systems. Traditional cleaning methods, such as chemical cleaning and high-pressure water blasting, can be energy-intensive, leading to increased greenhouse gas emissions and higher operational costs. In contrast, energy-efficient condenser tube cleaning systems are designed to minimize power consumption while achieving effective cleaning results. Technologies such as ultrasonic cleaning, which uses sound waves to remove deposits, often require less energy compared to mechanical and chemical cleaning methods. Additionally, some modern systems incorporate energy-saving features, such as variable-speed drives and intelligent control systems, to optimize power usage based on cleaning needs. By comparing the energy consumption and efficiency of different cleaning systems, industries can make informed decisions that reduce their carbon footprint, lower energy costs, and contribute to overall environmental sustainability.

Condenser Tube Cleaning Systems In Minimizing Harmful Byproducts And Emissions

Minimizing harmful byproducts and emissions is a key objective for environmentally responsible condenser tube cleaning systems. Traditional cleaning methods can produce harmful byproducts, such as chemical residues and particulate matter, which may be released into the environment during cleaning processes. For instance, chemical cleaning often results in the generation of hazardous waste that requires proper disposal to prevent environmental contamination. In contrast, modern condenser tube cleaning systems are designed to reduce or eliminate harmful byproducts and emissions. Techniques such as ultrasonic cleaning and mechanical brushing produce minimal waste and do not rely on chemicals, thereby reducing the risk of pollution. Additionally, some systems feature advanced filtration and capture technologies that manage and contain byproducts, ensuring that emissions are minimized and handled safely. By focusing on reducing harmful byproducts and emissions, condenser tube cleaning systems contribute to a cleaner, healthier environment and support industry efforts to meet environmental regulations.

Environmental Standards For Modern Condenser Tube Cleaning Systems

Regulatory compliance and adherence to environmental standards are essential considerations for modern condenser tube cleaning systems. As environmental regulations become increasingly stringent, industries are required to adopt cleaning methods that meet specific standards for waste management, chemical usage, and emissions. Modern condenser tube cleaning systems are designed to comply with these regulations by incorporating features that address environmental concerns. For example, systems that use chemical-free cleaning methods or employ advanced waste management practices can help industries meet regulatory requirements related to chemical discharge and waste disposal. Additionally, some systems are certified to meet environmental standards, such as ISO 14001, which demonstrates a commitment to sustainable practices. By ensuring that condenser tube cleaning systems adhere to regulatory compliance and environmental standards, industries can avoid legal penalties, enhance their environmental performance, and contribute to global sustainability efforts.

Conclusion

The environmental impact of condenser tube cleaning systems is a crucial consideration for industries aiming to balance operational efficiency with ecological responsibility. From eco-friendly technologies and chemical-free methods to waste management practices and energy efficiency, various factors influence the environmental footprint of these systems. By adopting advanced cleaning solutions that minimize water usage, reduce harmful byproducts and emissions, and ensure regulatory compliance, industries can achieve effective condenser tube cleaning while supporting sustainability goals. As environmental concerns continue to shape industry practices, ongoing innovation and adherence to best practices will be essential in mitigating the impact of condenser tube cleaning systems and promoting a cleaner, more sustainable future.