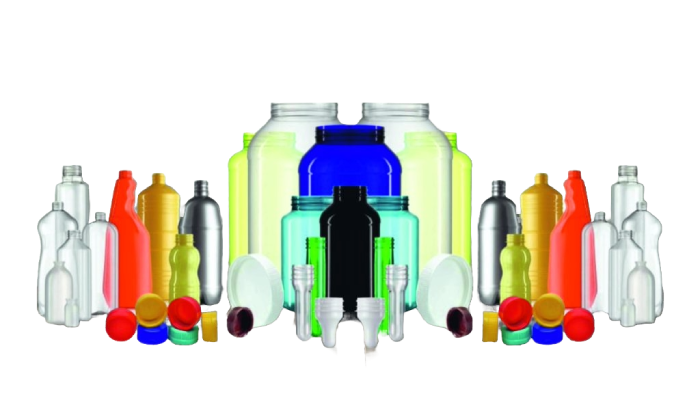

How to Check Pet Preform Quality in Delhi India?

Quality control for PET preforms in Delhi is key to ensuring safe and reliable packaging. It starts with using specific testing tools, like the preform perpendicularity tester, which checks for alignment. A top load tester evaluates the strength of bottles under pressure from storage. Measuring wall thickness with a gauge is also crucial; it maintains consistency and prevents issues like leaks or breakage. Other methods include a polariscope strain viewer to find internal defects and a transparency tester to ensure visual quality meets standards. Regular calibration of equipment and training operators helps keep these processes efficient, ultimately enhancing product trust among consumers.

1. Understanding PET Preform Quality Standards

To gauge the quality of PET preform in delhi india, one must first understand the relevant industry standards, such as ASTM and ISO. These standards outline specifications for dimensions, shape, and weight, which are crucial for ensuring that preforms can produce reliable and safe end products. Material purity also plays a vital role; high-quality raw materials are essential for producing preforms that can withstand the rigors of their intended use. Consistent production processes are equally important, as variations can lead to defects that compromise the integrity of the final products.

Recyclability and sustainability are becoming key factors in material selection, especially as consumers become more eco-conscious. This consideration extends to local regulations in Delhi, which may impose specific quality requirements that manufacturers must meet. Batch testing is another crucial aspect of quality assurance, helping to ensure that each batch of preforms maintains the same high standards. Third-party certifications can further enhance confidence in product quality, providing an independent verification of adherence to established standards.

Lastly, consumer expectations significantly influence quality standards. As customers demand higher quality and safety, manufacturers must adapt to meet these expectations, reinforcing the importance of robust quality control measures throughout the production process.

- Review industry standards such as ASTM and ISO for PET preforms.

- Identify specifications for dimensions, shape, and weight of preforms.

- Understand the role of material purity in preform production.

- Evaluate the importance of consistent production processes in quality assurance.

- Assess the significance of recyclability and sustainability in material selection.

- Examine the influence of preform quality on end-user safety and satisfaction.

- Study how local regulations in Delhi impact preform quality standards.

- Recognize the importance of batch testing for consistency.

- Analyze the role of third-party certifications in quality assurance.

- Discuss the impact of consumer expectations on preform quality standards.

2. Essential Testing Instruments for PET Preforms

To ensure the quality of PET preforms, several key testing instruments are essential. The Preform Perpendicularity Tester assesses the alignment of preforms, ensuring uniformity for the bottles produced. A Top Load Tester simulates the compressive forces preforms will face during transport, ensuring strength and durability. The Preform Thickness Gauge measures wall thickness, which is crucial for preventing weak points that could lead to breakage. The Polariscope Strain Viewer detects internal stresses and defects, using polarized light to identify potential issues. A Transparency Tester checks the clarity of preforms, vital for the aesthetic appeal of consumer products. Lastly, the Deflection Temperature Tester determines the temperature at which preforms start to deform under stress, essential for the blow molding process.

When comparing manual versus automated testing methods, automated systems offer greater efficiency and consistency, reducing human error and increasing throughput. However, manual methods can be more cost-effective for small manufacturers who may not have the budget for automation. Calibration of testing instruments is critical to ensure accuracy, and regular calibration procedures should be established to maintain the reliability of measurements. Modern technology plays a significant role in enhancing testing capabilities, with software available for data analysis that helps manufacturers track trends and make informed decisions.

Integrating testing instruments into the production line can streamline processes and minimize downtime. Regular maintenance of testing equipment is also vital, as it prevents malfunctions that could lead to costly production delays. For small manufacturers, cost-effective options like portable testing devices can still provide reliable results without a large financial investment. Emerging technologies, such as advanced imaging systems and real-time monitoring tools, are paving the way for more precise and efficient testing methods in the PET preform industry.

3. Evaluating Preform Alignment and Shape

Evaluating the alignment and shape of PET preforms is crucial for ensuring the quality of the final bottle products. Acceptable preform shape should be consistent, symmetrical, and free from any visible defects. Misalignment can lead to significant issues during bottle production, including uneven walls and improper sealing, which affects the strength and performance of the bottles. To assess alignment, manufacturers often use a preform perpendicularity tester, which checks that the preform is straight and conforms to the desired specifications. Misalignment can stem from various factors, such as improper cooling during manufacturing or issues with the injection molding process.

Visual inspection is another key method for checking preform shape. Operators should look for any irregularities, such as warping or uneven edges. Common defects include oval shapes instead of circular ones and inconsistent neck dimensions, often caused by poor mold design or material distribution.

Advanced technologies, such as 3D imaging, enhance shape analysis by providing detailed visual data, allowing for precise identification of defects that might not be visible to the naked eye. Automated shape detection systems can streamline this process further, rapidly identifying misaligned preforms and reducing human error. Consistent preform dimensions are essential, as they directly impact the efficiency of the blow molding process and the overall production timeline. Addressing alignment issues promptly can involve recalibrating machinery, adjusting the cooling process, or redesigning molds to improve uniformity. Examining case studies of past misalignment problems can provide valuable insights into best practices and corrective measures.

4. Assessing Bottle Strength with Top Load Tests

Top load testing is a method used to evaluate the strength of PET bottles by simulating the compressive forces they experience during storage and transport. This testing is crucial in the quality assurance process, as it helps manufacturers determine whether their bottles can withstand the weight of other bottles stacked on top without deforming or failing.

The procedure for conducting top load tests involves placing a bottle on a testing platform and applying a predetermined load until the bottle fails or reaches its maximum strength. This process measures the amount of weight the bottle can bear, which is essential for ensuring product safety and integrity. Acceptable strength parameters for PET bottles typically range from 10 to 20 kilograms for standard bottles, but this can vary based on the bottle design and intended use.

Poor bottle strength can lead to serious implications for product safety, including leaks, breaks, and contamination of contents, which can be catastrophic in industries like food and pharmaceuticals. Different preform designs can significantly affect bottle strength; for instance, a wider base may increase stability but could also alter the aesthetics of the bottle.

Industry benchmarks for top load capabilities generally require bottles to withstand specific weights without showing signs of deformation, ensuring they meet consumer expectations and regulatory standards. The relationship between material properties and bottle strength is also critical; for example, variations in the PET resin used can influence the overall strength and durability of the finished product.

Environmental factors, such as temperature and humidity, can further impact top load performance, as extreme conditions may weaken the material over time. Testing protocols must account for different bottle sizes and shapes, as these variables can affect the results of top load tests. Real-world examples of strength testing outcomes demonstrate that bottles failing to meet the required standards can lead to increased costs and reduced consumer trust, highlighting the importance of rigorous testing in the manufacturing process.

5. Measuring Wall Thickness for Durability

Wall thickness is a crucial aspect of PET preforms that directly affects their overall strength and durability. A consistent wall thickness ensures that the preform can withstand the pressures of production and the stresses encountered during transportation and storage. Measuring this thickness accurately is essential, and several methods can be employed, such as using a preform thickness gauge or Ultrasonic thickness gauges. The acceptable thickness ranges can vary depending on the intended application, but generally, a range of 0.6 to 1.2 millimeters is common for most bottle designs.

Inconsistent wall thickness can lead to weak points in the final product, resulting in potential breakage or leaks. This inconsistency can also affect thermal resistance; thinner areas might not hold up under high temperatures, leading to deformation during the blow molding process. Moreover, maintaining an optimal wall thickness is critical for material savings; excessive thickness leads to unnecessary material use, while too thin a wall risks product integrity.

Ultrasonic thickness gauges are particularly advantageous as they provide non-destructive measurements, allowing manufacturers to check thickness without damaging the preforms. Regularly monitoring wall thickness helps identify common defects associated with improper measurements, such as uneven surfaces and stress points. Best practices for maintaining consistent wall thickness include regular calibration of measuring instruments, thorough training for operators, and implementing data tracking systems to monitor variations over time. Case studies of wall thickness failures underline the importance of vigilance in this area, showing that lapses in quality control can lead to significant production losses and safety issues.

6. Detecting Internal Defects in Preforms

Internal defects in PET preforms can significantly affect the quality of the final products. Common issues include crystallization defects, which occur when the polymer molecules become overly ordered, leading to weak spots. These defects can result in decreased strength and clarity in the finished bottles. To detect crystallization defects, using a polariscope strain viewer is essential. This device employs polarized light to visualize internal stresses, allowing manufacturers to identify problematic areas before production. Internal defects can compromise not only the physical integrity of the bottles but also their safety, as weak points are more prone to breakage during transport or use.

Routine inspections are vital for maintaining preform quality. Best practices include regular visual inspections to catch obvious defects, along with using precise instruments like the polariscope. Implementing non-destructive testing methods provides further benefits, as these techniques allow for thorough assessments without damaging the preforms. When defects are identified, it’s crucial to implement corrective measures promptly, such as adjusting processing parameters or retraining personnel. Training is key, as operators must understand how to use testing equipment effectively to ensure reliable results. Advancements in defect detection technologies continue to improve the accuracy and efficiency of these inspections, thus enhancing overall product quality.

7. Ensuring Aesthetic Quality through Transparency Tests

Transparency in PET preforms is critical, as it directly affects consumer perceptions of product quality. A clear, transparent preform suggests purity and high standards of manufacturing, which can significantly influence a buyer’s decision. Various methods can test the transparency of PET preforms, including visual inspection, light transmission tests, and specialized transparency testers. These tests help assess clarity and identify any defects, ensuring that preforms meet the visual standards expected in consumer products.

Acceptable transparency levels can vary by application. For example, beverage containers typically require higher transparency than industrial packaging, as consumers expect to see the liquid inside. Material clarity can impact consumer perception, with clear products often associated with freshness and quality, while cloudy or opaque preforms may raise concerns about contamination or inferior materials.

Color also plays a crucial role in branding, as companies often use specific hues to evoke emotions or convey messages. For instance, a beverage brand might choose a vibrant color to communicate energy and excitement, while a pharmaceutical product may opt for subdued tones to promote trust and safety. Transparency testing ensures that these colors remain true and vibrant, enhancing brand identity.

Furthermore, transparency is a reflection of material quality and purity. Impurities can lead to cloudiness, which not only affects aesthetics but may also signal potential issues with material safety. Industry standards for transparency in PET preforms exist to ensure that manufacturers maintain a high level of quality, with specific guidelines set forth by organizations such as the Food and Drug Administration (FDA) and the American National Standards Institute (ANSI).

Poor transparency can severely impact marketability. If products appear unappealing or of low quality, it can deter customers, leading to reduced sales and a damaged brand reputation. Case studies have shown that brands investing in quality control and transparency testing see tangible benefits in consumer trust and sales performance.

Common causes of transparency issues in manufacturing include improper processing conditions, contamination during production, and the use of inferior raw materials. Addressing these issues early in the manufacturing process can prevent costly recalls and maintain high standards of product quality.

8. Testing Temperature Resistance in Preforms

Temperature resistance refers to a material’s ability to maintain its properties when exposed to varying temperatures. This characteristic is crucial for PET preforms, as they undergo significant thermal changes during the blow molding process and in end-use applications. Testing the thermal performance of preforms can be done using several methods, such as the Deflection Temperature Tester, which evaluates the temperature at which the preform begins to deform under stress, ensuring that it can withstand high temperatures.

Acceptable temperature resistance parameters depend on the intended use of the final product. For example, preforms for beverage bottles may need to endure temperatures from freezing to boiling, while those for pharmaceutical containers may have different requirements based on the stored substances. Fluctuations in temperature can compromise the integrity of preforms, leading to deformation or failure during production and use.

Testing protocols for heat resistance involve subjecting preforms to controlled temperature variations and measuring any changes in shape or performance. This is especially relevant during blow molding, where preforms are heated before being shaped into bottles. Material composition also plays a significant role in thermal performance; for instance, the addition of certain additives can enhance heat resistance.

Industry standards for temperature resistance testing provide guidelines for manufacturers to ensure their products meet necessary safety and performance benchmarks. Real-world scenarios, such as a preform used in a hot climate or for hot-fill applications, highlight the importance of temperature resistance in maintaining product quality. Best practices for ensuring high temperature resistance include selecting the right materials, conducting regular testing, and adhering to established industry standards.

9. Implementing Best Practices for Quality Control

An effective quality control program for PET preforms includes several key elements. First, it is essential to establish regular training and certification for staff, ensuring that everyone involved understands the importance of quality and knows how to operate testing instruments correctly. Documentation plays a critical role in quality control processes, allowing for accurate record-keeping and easy reference during audits or quality assessments. This documentation helps track trends over time and identify areas for continuous improvement.

Setting clear quality benchmarks and objectives is another best practice. These benchmarks provide a target for production teams and help maintain consistency in quality. Integrating quality control with production processes ensures that quality checks happen seamlessly at various stages of production, minimizing the risk of defects.

Feedback loops are crucial in quality management, as they allow for real-time adjustments based on findings from quality assessments. Leadership also plays a significant role in fostering a quality culture, encouraging open communication about quality issues and promoting accountability.

Technology impacts quality control practices significantly, with advancements in testing instruments and data analytics enhancing precision and efficiency. Compliance with certifications and standards not only boosts product credibility but also demonstrates a commitment to maintaining high-quality output.

10. Advantages of Maintaining High Quality in Production

Maintaining high quality in the production of PET preforms offers significant economic benefits. Quality preforms reduce the likelihood of product failures, leading to long-term savings on replacements and recalls. Moreover, a strong commitment to quality enhances brand reputation, making businesses more attractive to consumers. When customers know they can rely on a brand for consistent quality, it fosters loyalty and encourages repeat purchases.

In addition, high-quality production minimizes waste and the need for rework, which can be costly and inefficient. Companies that prioritize quality often experience higher employee morale since workers take pride in producing reliable products. A strong quality assurance program can also create a competitive advantage, helping businesses stand out in a crowded market.

Furthermore, maintaining high-quality standards is crucial for regulatory compliance, which can protect a company from legal issues and fines. Real-world examples, such as companies that have implemented Total Quality Management (TQM) strategies, demonstrate that a focus on quality can lead to increased market share and customer satisfaction. As consumer expectations continue to evolve, businesses must adapt by prioritizing quality to meet rising standards.

Frequently Asked Questions

What should I look for when checking the quality of pet preforms in Delhi?

When checking pet preform quality, focus on several key factors like their clarity, consistency in thickness, any visible defects, and how well they hold their shape under pressure.

How can I test the strength of pet preforms?

You can test the strength of pet preforms by performing a pressure test or by examining how they respond to heat, ensuring they don’t warp even when subjected to temperature changes.

What are the signs of poor-quality pet preforms?

Signs of poor-quality pet preforms include visible bubbles, uneven surfaces, color inconsistencies, and any cracks or weak spots that might affect their performance.

Do I need special tools to assess pet preform quality?

While some assessments can be done by eye, having tools like calipers for measuring thickness or a microscope for checking clarity can provide a more detailed evaluation.

How important is it to choose high-quality pet preforms?

Choosing high-quality pet preforms is crucial as they directly affect the safety, durability, and performance of the final product you create, ensuring customer satisfaction.

TL;DR To ensure high-quality PET preforms in Delhi, it’s crucial to follow standard quality control methods. Use essential testing instruments like a preform perpendicularity tester to evaluate shape accuracy, a top load tester for assessing bottle strength, and a thickness gauge for measuring wall durability. Detect internal defects with a polariscope, check clarity using a transparency tester, and confirm temperature resistance with a deflection temperature tester. Regular calibration, operator training, and effective data tracking enhance quality control. Prioritizing these practices leads to durable products, reduced waste, and increased consumer trust.