How to Choose a Drink Bottle Manufacturer in Delhi India?

Choosing a drink bottle manufacturer in Delhi, India, requires careful thought and planning. First, understand your product needs by identifying the type of bottle you want, whether it’s plastic or stainless steel, and its size. Next, consider the production capacity to ensure they can scale as demand grows. Quality is crucial; check for necessary certifications like ISO and ISI to confirm safety standards. Transparency in pricing is key to avoiding unexpected costs. Also assess lead times for timely deliveries and consider eco-friendly options that align with consumer values today. Finally, verify the manufacturer’s reliability through reviews and inquire about customization opportunities that could help your brand stand out in the market.

1. Understanding Your Needs for Drink Bottles

To effectively choose a drink bottle manufacturer in Delhi india, it’s crucial to first understand your specific needs for the bottles. Begin by identifying the type of drink bottle you require: are you looking for reusable, disposable, or insulated options? Each type serves different purposes and appeals to distinct market segments. Next, consider the primary use of the bottles. Are they intended for water, sports drinks, or perhaps other beverages?

Research current trends in bottle designs that resonate with consumers. Features like ergonomic shapes and vibrant colors can make a significant difference in attracting buyers. Assess the volume of liquid each bottle should hold to ensure it meets customer demands. For instance, if targeting fitness enthusiasts, a 750ml bottle might be ideal for hydration during workouts.

Specialized features can also set your product apart. Consider if you need built-in straws, filters, or infusers for adding flavor to water. Branding elements are equally important; think about how logos and colors can enhance your drink bottle’s appeal.

Understanding your target market’s demographics is essential. Factors like age, lifestyle, and preferences for sustainability should guide your decisions. Gathering feedback from potential customers can provide invaluable insights into the features they value most. Additionally, analyzing competitors’ offerings can help you identify gaps in the market that your bottles could fill. Finally, compile a detailed product specification document that outlines all your requirements. This will serve as a vital reference when communicating with manufacturers.

- Identify the specific type of drink bottle you need, such as reusable, disposable, or insulated.

- Consider the primary use of the bottles, whether for water, sports drinks, or other beverages.

- Assess the volume of liquid each bottle should hold to meet customer needs effectively.

- Determine if specialized features are required, like built-in straws, filters, or infusers.

- Take into account the branding elements, such as logos or colors, you want to incorporate into the bottle design.

- Evaluate the demographics of your target market, including age, lifestyle, and preferences for sustainability.

- Gather feedback from potential customers about what features they value most in drink bottles.

- Analyze competitors’ offerings to identify gaps in the market that your bottles could fill.

2. Assessing Production Capacity and Scalability

When choosing a drink bottle manufacturer, it’s crucial to assess their production capacity and scalability. Start by investigating their current production volumes to ensure they can meet your initial order size without issue. Ask about their capabilities during peak seasons, like holidays or product launches, to understand how they manage increased demand. It’s also important to check if they have modern machinery and technology that efficiently handle large orders. Inquire about their workforce and if they can scale up staffing for larger orders.

Additionally, look into their inventory management practices to ensure they can supply materials in a timely manner. Understanding their lead times for both small and large orders will help you plan your supply chain effectively. Evaluate their flexibility in adjusting production schedules based on your business needs, as this can be vital during unexpected growth phases.

Lastly, ask about their experience working with similar clients who have scaled their orders over time. This insight can reveal how well they handle growth and whether they have a solid supply chain to prevent delays. Confirm their ability to accommodate custom orders and modifications, as this may be essential for your product differentiation.

3. Quality Standards and Certifications

When selecting a drink bottle manufacturer in Delhi, understanding their quality standards and certifications is crucial. Request copies of relevant certifications that prove their quality control processes, such as ISO 9001. This certification indicates that the manufacturer has a quality management system in place, ensuring that they consistently meet regulatory and customer requirements.

Inquire about their testing procedures for both materials and finished products. Ask how often they conduct internal audits to maintain compliance with quality standards. It’s also important to evaluate their approach to handling quality issues and recalls, should they arise. A proactive strategy for addressing defects shows a commitment to product integrity.

Additionally, look for customer feedback regarding product quality and consistency over time. Manufacturers who prioritize quality will often have a track record free from significant quality issues or customer complaints. Consider certifications that demonstrate eco-friendly practices, like FSC or Green Seal, reflecting their commitment to sustainability.

Lastly, verify if they provide warranties or guarantees on their products, serving as a sign of their confidence in quality assurance. This kind of assurance can help you feel more secure in your partnership with the manufacturer.

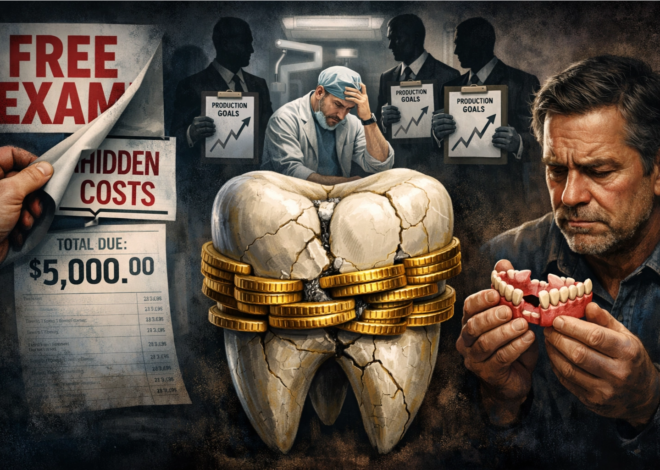

4. Evaluating Pricing Structure and Transparency

When choosing a drink bottle manufacturer, understanding their pricing structure is crucial. Start by requesting a detailed quote that lists all costs related to both production and delivery. This transparency helps you avoid unexpected charges later on. Comparing prices among different manufacturers can give you a sense of the market rate. Don’t hesitate to ask about bulk order discounts or loyalty programs, as they can significantly reduce costs for larger orders.

It’s important to clarify the pricing model being used. Some manufacturers charge per unit, while others may charge per batch or use a combination of both. Be cautious of hidden fees that might arise from shipping, handling, or customization services. Evaluating the type and quality of raw materials used is also essential, as this can impact overall pricing. For instance, high-quality stainless steel may come at a premium but could be worth the investment for durability.

Additionally, inquire about potential price fluctuations due to market conditions or material availability. Manufacturers should provide clarity on how they handle price adjustments for future orders, ensuring you have a clear understanding of how costs might change over time. Ultimately, ensure the pricing aligns with the quality and features you need in your bottles, as a good balance will help you maintain profitability while meeting customer expectations.

5. Understanding Lead Time and Logistics Support

When selecting a drink bottle manufacturer, it is crucial to understand their lead time and logistics support. Start by asking about their standard lead times for production and shipping. This helps you set realistic expectations for when you can expect your order to arrive. If you have urgent needs, inquire about their capability to handle expedited orders and shipping options.

Assess their logistics partners and shipping methods to ensure reliability and cost-effectiveness. It’s important to be aware of any potential delays that could arise from customs or regulatory checks if you plan to ship internationally. Additionally, checking if they offer tracking services for shipments can keep you informed throughout the delivery process.

Evaluate their warehousing capabilities too, especially if you need assistance managing inventory. Clear communication about your delivery needs can help gauge their responsiveness and adaptability. Knowing the distance between your location and the manufacturer will also aid in logistics planning.

Lastly, ask how they address issues like damaged or lost shipments, as well as their policies for replacements. Ensure they can provide the necessary documentation for smooth customs clearance if shipping outside India.

6. Compliance with Eco-Friendly Standards

When selecting a drink bottle manufacturer, it’s essential to ensure they comply with eco-friendly standards. Look for manufacturers that use sustainable materials, such as recycled plastics or biodegradable options, as this can significantly impact the environment. Inquire about their waste management practices during production, as efficient waste handling reflects a commitment to sustainability. Certifications can also play a vital role; check if the manufacturer holds any eco-friendly certifications that demonstrate their commitment to environmentally responsible practices.

Assessing their energy consumption and efforts to reduce carbon footprints during production is another critical factor. Understand their policies for sourcing materials responsibly and ethically, as this can contribute to a more sustainable supply chain. Manufacturers who participate in environmental initiatives or hold relevant certifications can indicate a genuine commitment to eco-friendly practices.

Additionally, ask about their recycling programs for used bottles or production waste, as these initiatives can further mitigate environmental impact. Keep in mind that adopting eco-friendly practices not only helps the planet but can also enhance your brand image in the market, appealing to increasingly environmentally conscious consumers. While there may be potential cost implications when choosing eco-friendly materials, the long-term benefits often outweigh these considerations. Finally, research consumer preferences for sustainable products in your target market to ensure your choices align with current trends.

7. Avoiding Common Mistakes in Selection

When selecting a drink bottle manufacturer, you can avoid common pitfalls by creating a checklist of essential criteria to evaluate each option. First, don’t assume that the cheapest choice will offer the best value; prioritize quality over price. Remember, poor quality can lead to costly product failures down the line. Customer service also matters, so investigate how well potential manufacturers support their clients during the process.

It’s wise to ask about the manufacturer’s experience in producing drink bottles. A manufacturer with a solid track record will have the expertise to meet your needs effectively. Be wary of those who make unrealistic promises about prices or delivery timelines, as this can be a red flag. Before committing to a bulk order, always request samples to assess the quality firsthand.

Avoid making decisions based solely on your personal preferences; consider market research and consumer feedback to guide your choices. Clear communication regarding your needs and expectations from the start is essential. This can prevent misunderstandings later on. Additionally, thoroughly read contracts to clarify terms and ensure there are no surprises. Finally, maintain a long-term perspective: while immediate costs are important, think about the overall partnership and the potential for growth.

8. Evaluating Manufacturer Reliability

When selecting a drink bottle manufacturer in Delhi, assessing their reliability is crucial. Start by researching their business history, including how long they have been in operation and any notable past performance. Look for customer testimonials and case studies that highlight their reliability over time. Inquire about their client retention rates, as high retention often indicates satisfaction with their products and services. Asking for references from other businesses in your industry can also provide valuable insight into their reliability.

Evaluating financial stability is another key aspect. A manufacturer should demonstrate the ability to meet your needs in the long run, which involves ensuring they have solid financial backing. Furthermore, check if they have a proven track record of on-time deliveries and quality assurance. This is essential for maintaining your own production schedule and meeting customer demands.

Communication style and responsiveness are also important indicators of reliability. A manufacturer that is easy to reach and quick to respond to inquiries can help build a strong partnership. Additionally, inquire about their contingency plans for unexpected challenges or delays; understanding how they manage such situations can give you peace of mind.

Lastly, assess their approach to managing client relationships and resolving disputes. A reliable manufacturer should prioritize open communication and be willing to address any concerns that arise. It is also important to understand their capacity to handle your specific needs and any potential challenges, ensuring they can adapt to your requirements as your business grows.

9. Customization and R&D Capabilities

When selecting a drink bottle manufacturer, it’s essential to explore their customization and research and development (R&D) capabilities. Start by asking about the range of customization options they offer for your drink bottles, such as size, color, and material. A manufacturer with a dedicated R&D team can significantly enhance your product design and development process. This team should be able to create prototypes based on your specifications, allowing you to visualize the final product before mass production.

Evaluate their experience with innovative designs or unique features that can help your product stand out in a crowded market. It’s also important to assess how quickly they can adapt to any changes in your design requirements, which is crucial for staying responsive to market demands. Understanding their process for gathering and implementing customer feedback into new designs can also provide insights into their commitment to continuous improvement.

Inquire about their willingness to collaborate on new ideas or product lines, as a cooperative relationship can lead to exciting new offerings. Additionally, consider their technical capabilities in producing complex or specialized designs; this can play a significant role in your product’s success. Finally, check if they have a track record of successfully launching similar customized products, as this experience can be invaluable during your own product launch. A manufacturer that provides strong support during the design and launch phases can make a significant difference in your overall experience.

10. Post-Production Support and Communication

When selecting a drink bottle manufacturer, it’s crucial to consider their post-production support and communication practices. Establishing clear channels for addressing any post-production issues can save you time and stress. You should inquire about their policies for handling defective products or returns, as knowing how they manage these situations helps protect your investment. It’s also important to ask about the process for warranty claims, so you understand what steps you’ll need to take if a product fails.

Evaluate their responsiveness to customer inquiries after delivery; a manufacturer that prioritizes communication can make a significant difference in resolving issues quickly. Additionally, it’s wise to understand how they handle product recalls, if necessary, to safeguard your brand’s reputation. Check if they provide training or resources to help you use their products effectively, as this can enhance customer satisfaction.

Consider their capacity for ongoing support, such as updates or product enhancements, which can be essential for keeping your offerings current. Inquire about any additional services they might provide, like marketing or promotional support, which can further assist your business.

Finally, assess their commitment to maintaining a long-term relationship with their clients, as a dedicated support team can be invaluable for ongoing communication and assistance.

Frequently Asked Questions

What factors should I consider when choosing a drink bottle manufacturer in Delhi?

When selecting a drink bottle manufacturer in Delhi, think about their experience, production capacity, quality of materials, customization options, and customer reviews. These factors can help ensure you partner with a reliable manufacturer.

How can I ensure the quality of bottles from a manufacturer?

You can check the manufacturer’s certifications, ask for samples, and review their production processes. It’s also helpful to read customer testimonials to get a sense of the quality they provide.

What kind of customization options should a good manufacturer offer?

A good manufacturer should offer options like size, color, material, printing, and branding. These allow you to create a drink bottle that fits your needs perfectly.

What is the importance of sustainability in choosing a drink bottle manufacturer?

Sustainability is important because it reflects the manufacturer’s environmental responsibility. Choosing a manufacturer that uses eco-friendly materials and practices can enhance your brand’s appeal and reduce your impact on the environment.

How do I find reputable drink bottle manufacturers in Delhi?

You can find reputable manufacturers by researching online, reading reviews, seeking recommendations from industry contacts, and visiting trade shows. Networking can also help you connect with reliable suppliers.

TL;DR Choosing a drink bottle manufacturer in Delhi involves understanding your specific needs, assessing production capacity and scalability, and ensuring quality standards and certifications. Evaluate pricing transparency, lead time, and logistics support, while ensuring compliance with eco-friendly practices. Avoid common mistakes like choosing solely based on price or ignoring cap compatibility. Research manufacturer reliability, seek customization options and R&D capabilities, and ensure post-production support is in place. By prioritizing these factors, you can find a manufacturer that aligns with your brand’s goals.

resource URL: