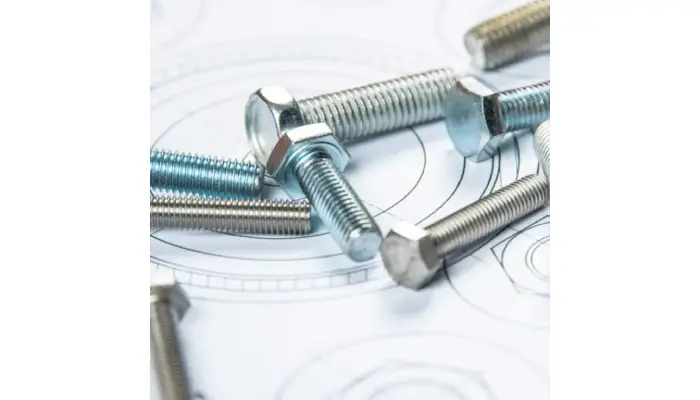

What Makes a Screw Manufacturing Company Reliable?

When it comes to the world of manufacturing, screws may seem like a small component. However, they play a critical role in countless products across various industries. From automotive to construction, the demand for high-quality screws is ever-present. That’s where screw manufacturing companies come into play. But how do you sift through the myriad of options available? The answer lies in reliability.

Choosing a trustworthy screw manufacturer can make all the difference in your projects’ success. A reliable partner ensures that you’re not just getting any screws but those that meet strict quality standards and performance expectations. But what makes one screw manufacturing company stand out from another? Let’s dive into key factors that define reliability and help you find the right supplier for your needs.

The Importance of Reliability in Choosing a Screw Manufacturer

Choosing a screw manufacturing company in India involves more than just price comparisons. Reliability is crucial in this decision-making process. A dependable manufacturer ensures that the screws you receive meet industry standards, preventing costly delays and safety issues.

When projects hinge on precise specifications, having a reliable partner can make all the difference. Flawed or substandard screws can lead to structural failures and compromised integrity, affecting both reputation and bottom line.

Additionally, reliability fosters trust between manufacturers and their clients. When you know your supplier consistently delivers quality products on time, it allows for smoother operations and better planning.

In an industry where every detail matters, working with a trustworthy screw manufacturer isn’t just beneficial—it’s essential for long-term success. The stakes are high; choosing wisely pays off in the end.

Factors that Make a Screw Manufacturing Company Reliable

Quality control is crucial for a reliable screw manufacturing company. A robust quality management system ensures that every product meets industry standards and customer expectations. This commitment to excellence minimizes the risk of defects.

The technology and equipment employed also play a significant role. Advanced machinery enhances precision in production, leading to consistently high-quality screws. Companies that invest in modern technology often yield better results.

Experience matters too. An established manufacturer brings valuable insights gained over years in the industry. Their expertise can guide customers toward the right products for their specific needs.

Customer reviews provide insight into reliability. Satisfied clients often reflect a company’s commitment to service and quality. Positive feedback indicates trustworthiness, while negative reviews should raise red flags when selecting a manufacturer.

Quality Control Processes

Quality control processes are the backbone of any reputable screw manufacturing company. These procedures ensure that each product meets stringent standards before it leaves the factory.

A reliable manufacturer implements rigorous testing at various stages of production. This might include dimensional inspection, tensile strength tests, and surface finish evaluations. Each test plays a crucial role in verifying that screws will perform as expected under real-world conditions.

Additionally, many companies adopt internationally recognized quality management systems like ISO 9001. Such certifications signal a commitment to maintaining high-quality benchmarks consistently.

The use of advanced technologies also enhances quality control measures. Automation and precision machinery can minimize human error and increase accuracy throughout the manufacturing process.

A well-defined quality control process not only builds trust with customers but also fosters long-term partnerships within industries reliant on dependable fasteners.

Technology and Equipment Used

Modern screw manufacturing relies heavily on advanced technology and equipment. Sophisticated machinery enhances precision in production, ensuring that each screw meets strict specifications.

CNC (Computer Numerical Control) machines play a crucial role in the process. They allow for automated cutting, shaping, and threading of screws with remarkable accuracy. This reduces human error and increases efficiency.

Additionally, manufacturers are adopting 3D printing technologies to prototype new designs quickly. This innovation accelerates product development while maintaining high quality standards.

Robust quality assurance systems also depend on modern testing equipment. These tools assess tensile strength and corrosion resistance, essential factors for various applications.

Investing in state-of-the-art technology not only improves production capabilities but also reflects a commitment to excellence. A reliable screw manufacturing company continuously upgrades its machinery to stay competitive in an evolving market.

Experience and Expertise

Experience and expertise are cornerstones of a reliable screw manufacturing company. A seasoned manufacturer brings years of knowledge to the table, navigating industry challenges with ease.

Expertise in various materials and production methods allows these companies to create screws that meet diverse specifications. They understand how different alloys react under stress, ensuring durability in every piece produced.

Moreover, an experienced team is adept at problem-solving. When faced with design complexities or last-minute changes, they can pivot efficiently without compromising quality.

Additionally, long-standing relationships with suppliers often indicate reliability. These connections help ensure that raw materials are consistently sourced from trusted vendors, further enhancing product integrity.

Choosing a manufacturer steeped in experience means you benefit from their accumulated wisdom and proven track record. This leads to better products and smoother processes for all parties involved.

Customer Reviews and Satisfaction

Customer reviews provide invaluable insights into the reliability of a screw manufacturing company. They reflect real experiences from clients who have used their products and services.

Positive feedback often highlights consistent quality and timeliness in delivery, indicating that the manufacturer values customer satisfaction. When potential buyers see glowing testimonials, it instills confidence in choosing that particular company.

Conversely, negative reviews can serve as red flags. A pattern of complaints about defects or poor communication might suggest underlying issues within the manufacturing process or customer service approach.

A reliable screw manufacturer welcomes feedback and actively works to resolve concerns. This responsiveness shows they care about maintaining strong relationships with their customers while continuously improving their offerings.

Satisfied customers are likely to return for future projects and recommend the manufacturer to others in need of similar solutions.

Benefits of Choosing a Reliable Screw Manufacturer

Choosing a reliable screw manufacturing company brings numerous advantages that can significantly impact your projects. First, you gain access to superior products that meet stringent quality standards. High-quality screws reduce the risk of failures and enhance the durability of your assemblies.

A trustworthy manufacturer often offers consistent delivery times, ensuring that your production schedules stay on track. This reliability alleviates stress and helps maintain workflow continuity.

Moreover, working with dependable suppliers fosters strong partnerships. Effective communication and responsive customer service create an environment where issues can be quickly resolved.

Cost efficiency is another noteworthy benefit. Reliable manufacturers tend to minimize waste through efficient processes, ultimately leading to better pricing options for their clients.

Partnering with a reputable manufacturer boosts your credibility in the marketplace. Clients trust companies that prioritize quality and reliability in their supply chain choices.

Tips for Finding a Reliable Screw Manufacturing Company

Start by researching potential screw manufacturing companies online. Look for those with a solid web presence and comprehensive product information.

Next, check their certifications and compliance with industry standards. A reliable manufacturer should meet ISO or similar quality management requirements.

Reach out to previous clients if possible. Their feedback can give you valuable insights into the manufacturer’s reliability and service level.

Visit facilities when feasible. Observing operations firsthand will help assess their technology, equipment, and overall working environment.

Don’t overlook customer support. A responsive team indicates good communication practices and commitment to client satisfaction.

Compare multiple options before making your decision. This ensures you find a company that aligns with your specific needs in terms of quality, pricing, and delivery schedules.

Case Study of a Successful and Reliable Screw Manufacturer

ABC Fasteners is a prime example of a successful screw manufacturing company. Established over three decades ago, they have built a reputation for quality and innovation.

Their commitment to stringent quality control processes ensures that every product meets industry standards. This has earned them long-term partnerships with major players in the automotive and construction sectors.

With state-of-the-art machinery and skilled technicians, ABC Fasteners consistently delivers precision-engineered screws. Their investment in technology allows for enhanced efficiency and reduced lead times.

Customer feedback plays a crucial role in their operations. Regular surveys indicate high satisfaction rates, reflecting their responsiveness to client needs.

This manufacturer’s focus on continuous improvement keeps them ahead of competitors. By adapting to market changes, ABC Fasteners remains at the forefront of the screw manufacturing industry.

Conclusion

Reliability plays a pivotal role in the success of screw manufacturing companies. When businesses choose a dependable manufacturer, they ensure consistent quality and timely delivery. This trust translates into long-term partnerships that foster growth and innovation.

A reliable screw manufacturing company often has robust quality control processes in place, utilizing advanced technology and equipment to maintain high standards. Their experience and expertise further enhance their credibility, making them a preferred choice for many industries.

Additionally, positive customer reviews indicate satisfaction levels that can set one manufacturer apart from another. The benefits of partnering with such companies are clear: reduced operational risks, improved product performance, and peace of mind knowing you’re working with professionals who prioritize excellence.

As you navigate the landscape of screw manufacturers, focusing on reliability will lead you to those companies that not only meet your needs but also contribute positively to your projects’ success. Trust is invaluable in this sector; it shapes relationships and drives results that matter most to your business’s bottom line.